#42 Marcela St., Damong Maliit, Brgy. Nagkaisang Nayon, Novaliches, Quezon City 1125, Metro Manila, Philippines

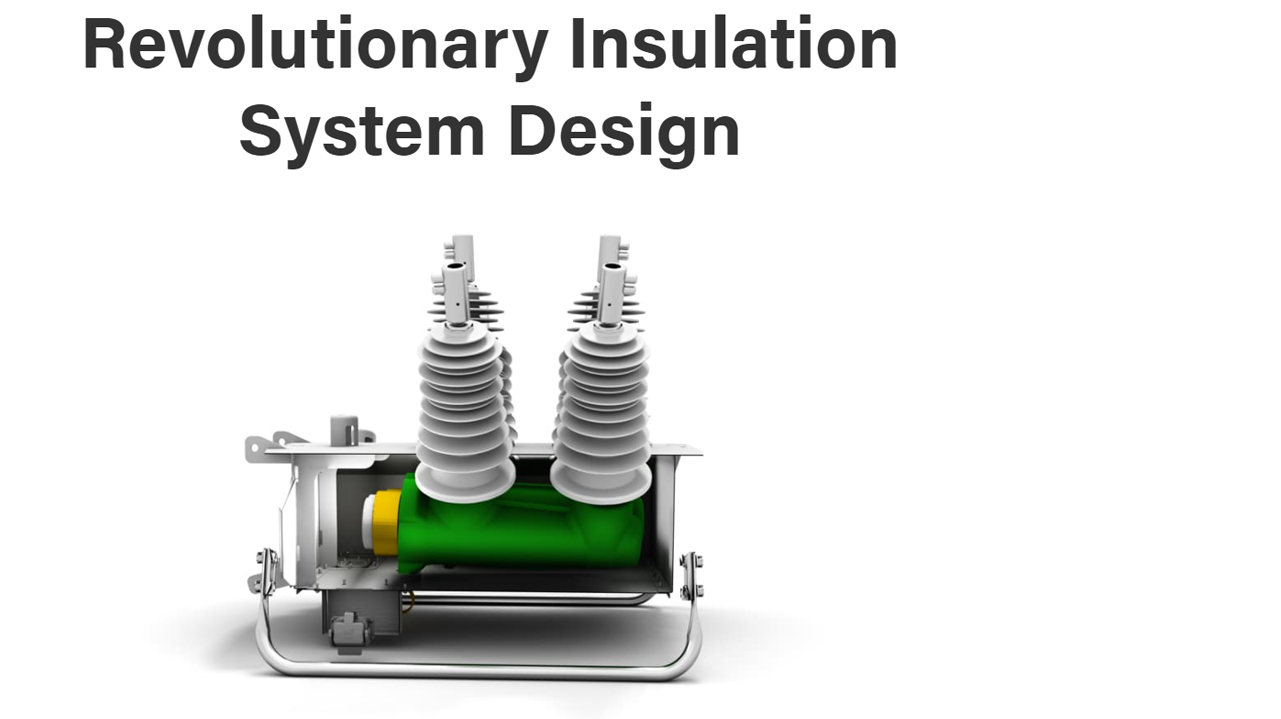

The OSM tank is manufactured from powder coated stainless steel and is arc-fault vented.

It has a 30 year operating design life.

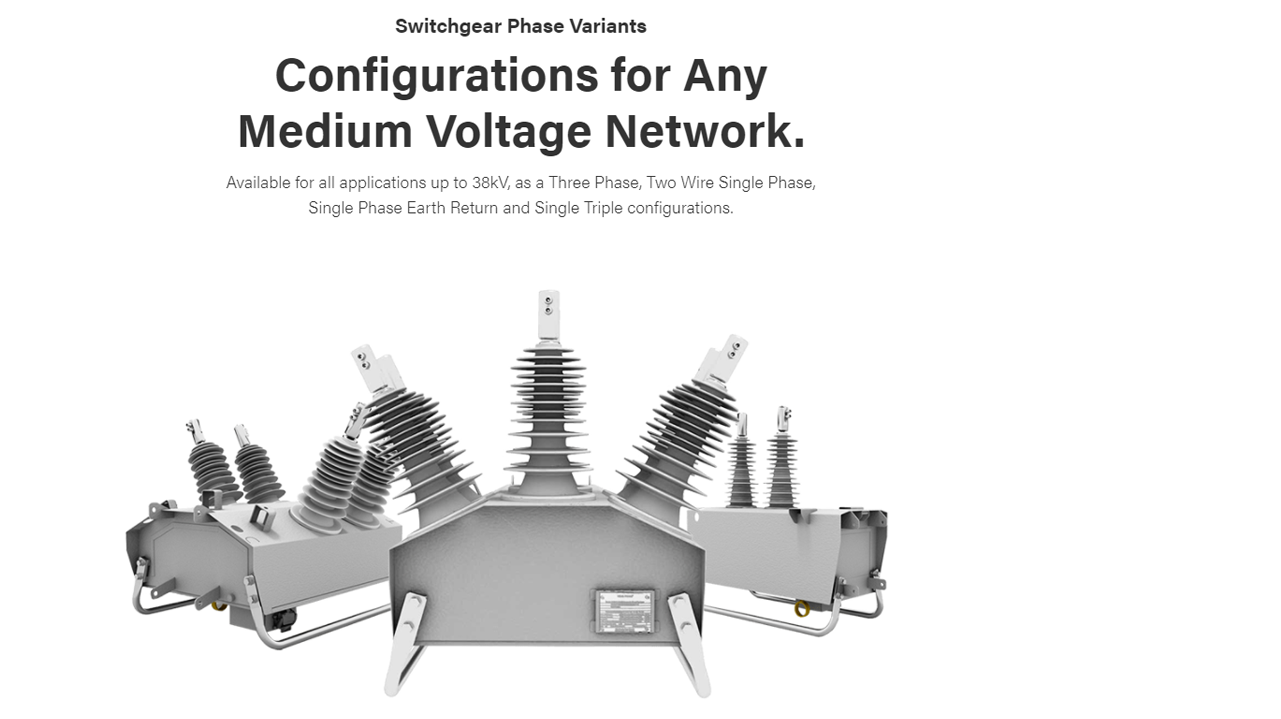

The OSM 300 and 310 Reclosers have three poles and the OSM 302 and 312 reclosers have two poles, each with its own vacuum interrupter and insulated drive rod contained within a solid dielectric housing. Each pole has its own magnetic actuator. The OSM tank provides an IP65 rating.

Energy for operation is provided by capacitors located in the Recloser Control (RC) Cubicle. The magnetic

actuators are mechanically interlocked, guaranteeing three phase simultaneous operation for 300 and 310

reclosers and two phase simultaneous operation for 302 and 312 reclosers. Magnetic latching holds the

mechanism in the closed position. Spring assisted trip operation is achieved by reversing actuator current

direction to generate a driving force in the opposite direction to a close operation.

The Recloser can be mechanically tripped by using a hook stick to pull the Mechanical Trip Ring downwards. Position indication is located in the base of the tank and can be viewed by an operator on the ground. Recloser open / close status is detected by the RC through monitoring the status of Auxiliary Switches that reflect the position of the mechanism. An optional mechanical trip counter is available.

Voltage is measured at all six terminals for the 300 and 310 reclosers and all four terminals for the 302 and 312 reclosers, using sensors that are capacitively coupled to the High Voltage (HV) terminals.

Current is measured on all three phases for the 300 and 310 recloser and two phases for the 302 and 312 recloser, using Current Transformers (CTs). These provide phase current measurement for indication, phase overcurrent protection and residual current measurement for indication and earth overcurrent protection. The Current Transformer secondaries are automatically shorted when the tank is disconnected from the control cubicle.

The main circuit Bushings are manufactured from aromatic epoxy resin. A silicone rubber Bushing Boot provides the required creepage distance. The Bushings have tin plated, brass connectors for termination of overhead cables. The Cable Connectors can be supplied in the form of Tunnel Terminals to suit cables up to 260 mm2, two-hole NEMA Palms and other types of terminations are available.

The same OSM Control Cable is common to all three models. Earthing point is an M12 bolt into the tank.

The Most Versatile Distribution Protection and Automation Asset in the Engineers Toolkit.

Protection, SCADA Communications and Smart Grid Automation in a Single Integrated System.